- About Alloy 20 Tubes

- Specification of Alloy 20 Tubes

- Stock availability of Alloy 20 Tubes

- Alloy 20 Tubes equivalent grades

- Chemical composition of Alloy 20 Tubes

- Mechanical properties of Alloy 20 Tubes

- Alloy 20 Tubes Dimensions Chart

- Alloy 20 Gauge Thickness chart

- Alloy 20 Tube outside diameter

- Specialized in Following Alloy 20 Tubes

- Searches related to Alloy 20 Tubes

- Alloy 20 Tubes Export Countries

- Supply of Alloy 20 Tubes in the Following Cities

What is Alloy 20?

Alloy 20 is made up of nickel, iron, and chromium elements. This alloy shows resistance to many acidic environments, and this alloy contains copper, which helps protect the product from sulfuric acid. Therefore, Company prefers this alloy to manufacture tubes.

UNS N08020 ALLOY 20 TUBING, ALLOY 20 SEAMLESS TUBE, ALLOY 20CB3 TUBES SUPPLIER IN MUMBAI, INDIA.

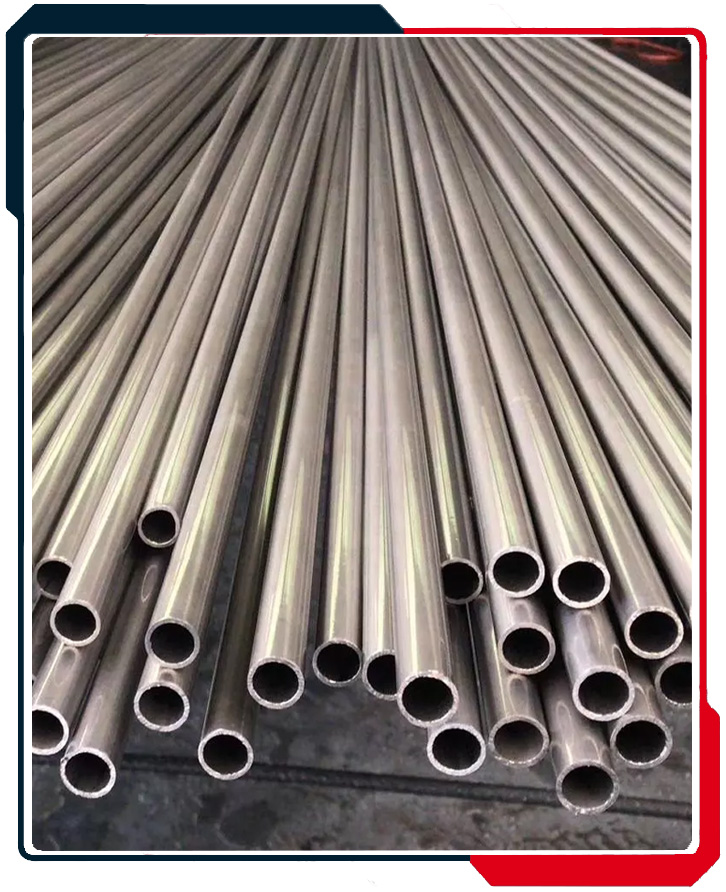

What are Alloy 20 tubes?

Company supplies two types of tubes, the seamless and welded tube. These alloy 20 tubes are designed for applications where sulfuric acid is involved. These alloy 20 tubes show resistance to pitting and chloride corrosion. In addition, it has excellent mechanical properties at high temperatures and fabricability. These tube ends are available in plain, threaded, and beveled. During the alloy sheets’ production, some niobium is added to them. Niobium has a stabilizing effect on the alloy 20 Tubes against sensitization as well as from the resultant decay by intergranular corrosion.